The global challenge of managing waste in an environmentally responsible and economically viable manner has spurred the adoption of sustainable waste management strategies. Among the innovative solutions contributing to these strategies, aluminum can baler have emerged as powerful tools for promoting resource conservation and circular economy principles. This article delves into how the integration of industrial compactors aligns with sustainable waste management strategies, fostering efficient waste handling, reducing environmental impact, and driving the shift towards a circular economy.

Resource Conservation through Waste Reduction:

Industrial garbage compactors play a pivotal role in resource conservation by significantly reducing the volume of waste generated by various industries. Traditional waste disposal methods often involve inefficient practices that lead to excessive waste volume occupying valuable space in landfills or incinerators. This approach not only wastes land resources but also contributes to higher disposal costs and environmental degradation. The integration of industrial compactors addresses this challenge by compacting waste materials, allowing businesses to make better use of available space and reduce the need for frequent waste removal.

Promoting Circular Economy Principles:

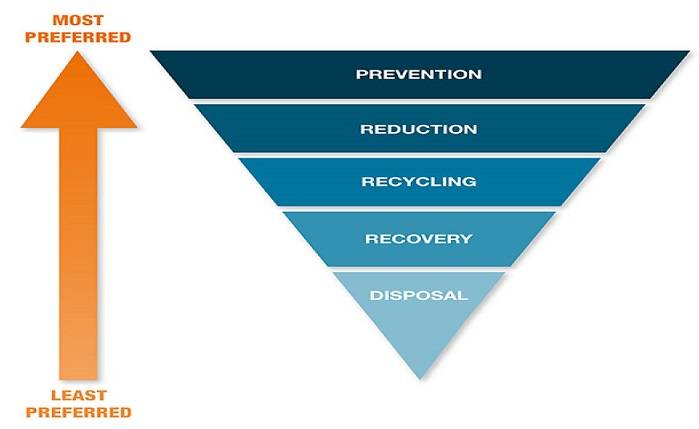

The circular economy concept envisions a shift away from the linear “take-make-dispose” model towards one that focuses on reducing waste and promoting the continuous use of resources. Industrial compactors align perfectly with this vision by aiding in waste minimization, resource recovery, and recycling efforts. Here’s how:

1. Waste Minimization: Industrial garbage compactors facilitate waste minimization at the source by compressing materials before disposal. This reduction in waste volume directly reduces the burden on landfills and the overall environmental footprint.

2. Enhanced Recycling Efforts: The reduced volume of compacted waste makes sorting and recycling more manageable. Separating recyclable materials from compacted waste streams becomes more efficient, increasing the likelihood of diverting valuable resources from landfills.

3. Resource Recovery: Compactors make it easier to recover valuable resources from waste streams, such as metals, plastics, and organic materials. These recovered resources can be processed and reintroduced into the production cycle, reducing the demand for virgin materials and conserving natural resources.

4. Reduced Greenhouse Gas Emissions: By decreasing waste volume and promoting recycling, industrial compactors indirectly contribute to the reduction of greenhouse gas emissions associated with waste disposal. This aligns with circular economy principles that seek to minimize negative environmental impacts.

Mobile Garbage Compactors: A Sustainable Solution

Mobile garbage compactors, in particular, offer unique benefits in the context of sustainable waste management. These compactors are designed to be easily transported to various waste generation points, making them suitable for locations such as urban centers, construction sites, and commercial complexes. Their mobility allows for on-site waste compaction, reducing the need for multiple waste collection trips and minimizing carbon emissions associated with transportation.

The compacted waste from mobile garbage compactors can be transported more efficiently to recycling centers or waste-to-energy facilities, further contributing to sustainable waste management practices. Additionally, the containment and compaction of waste in mobile compactors reduce the risk of littering, promoting a cleaner environment in public spaces.

Overcoming Challenges and Maximizing Impact:

While industrial garbage compactors offer substantial benefits, their successful integration into sustainable waste management strategies requires addressing potential challenges. These challenges can include proper waste segregation, operator training, maintenance schedules, and adapting to changing waste streams. Additionally, collaboration with waste collection and recycling partners is crucial to ensure that compacted waste reaches appropriate facilities for resource recovery.

To maximize the impact of industrial compactors on sustainable waste management, businesses should consider the following:

1. Comprehensive Waste Audits: Conduct regular waste audits to identify the types and volumes of waste generated. This information helps tailor waste management strategies and informs decisions about the appropriate use of compactors.

2. Educational Initiatives: Educate employees and stakeholders about waste reduction, segregation, and the benefits of compactors. Effective training ensures that waste is properly handled before it enters the compactor.

3. Continuous Monitoring and Maintenance: Implement regular maintenance schedules and monitor compactors’ performance to prevent downtime and ensure consistent waste compaction.

4. Collaboration with Recycling Facilities: Partner with recycling and waste-to-energy facilities to ensure that compacted waste is properly processed and diverted from landfills.

Conclusion: Towards a Greener Future

Incorporating industrial garbage compactor into sustainable waste management strategies offers a promising pathway towards a greener and more resource-efficient future. By reducing waste volume, enhancing recycling efforts, and promoting circular economy principles, compactors play a crucial role in minimizing waste generation and conserving valuable resources. As a key player in this sustainable journey, mobile garbage compactor exemplify the adaptability and innovation needed to transform waste management practices and contribute to a more environmentally conscious society.